Background

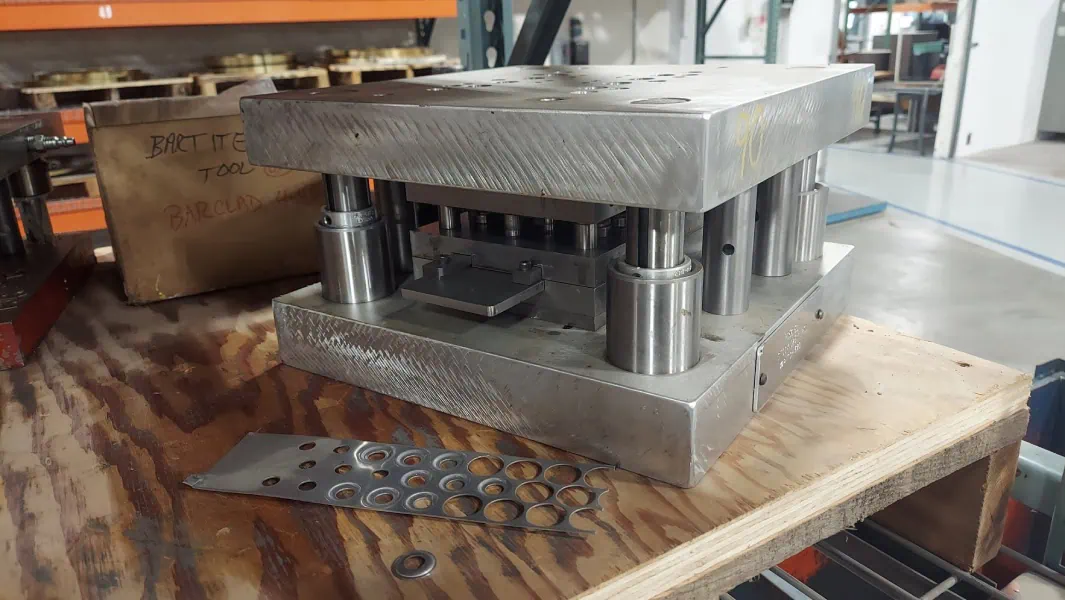

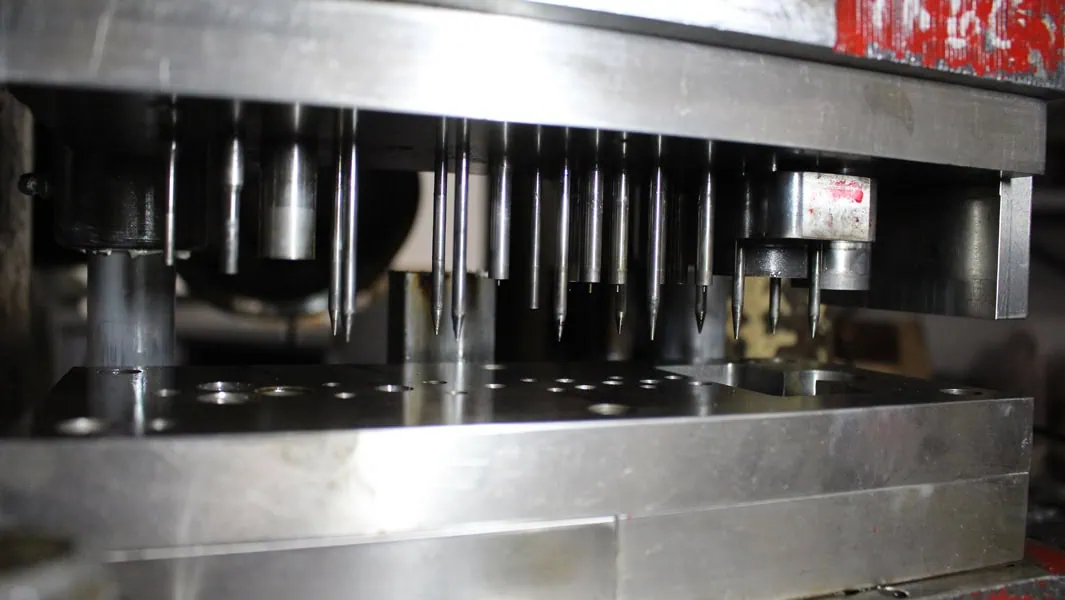

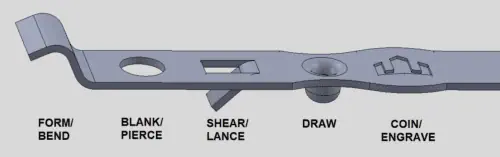

Metal Stampings are produced from strips of raw coiled stock fed through a tool known as a die which is actuated by a press. Multi-stage progressive dies are the most common but intricate dies, often used to achieve the desired part geometry over a series of stages/stations at a set pitch. Compound dies can be used to create (often flat) internal and external features (like a washer) in a single station. Other single-station tools require manually loading a blank instead of feeding a coil and individually cycling the press to alter the part. There are a variety of operations such as blanking, forming, coining, and deep drawing used to achieve the desired part geometry.

Our Process

From your part print, our qualified Engineers will design a die which is machined, assembled, and debugged by our experienced tool makers, for production in the press room by our skilled operators, entirely in-house in as little as one month. We use Carbide, CPM, A2, and D2 Tool steel among other materials in our dies which we can heat treat on-site for maximum die-life. We pride ourselves on precision and achieve the highest level of accuracy in our Wire EDM room, hitting tolerances within ±.0001”; the die itself is capable of producing parts within ±.001” consistently. Our metal stamping press room has (18) hydraulic presses, capable of 22-to-80-tons of stamping force for jobs small and large. Dies can produce millions of parts per year and are built to last many decades.

Die Protection

We utilize the latest techniques, safe-guards, sensors, feeders, ancillary equipment, and plan for preventative maintenance to maximize die life, giving our customers the following advantages:

- Eliminate die crashes

- Increase tooling and equipment up-time

- Higher strokes-per-minute

- Reduce maintenance costs

- On-time customer delivery

- One operator can run multiple presses simultaneously