United Tool & Machine’s Quality Assurance and Inspection Department…

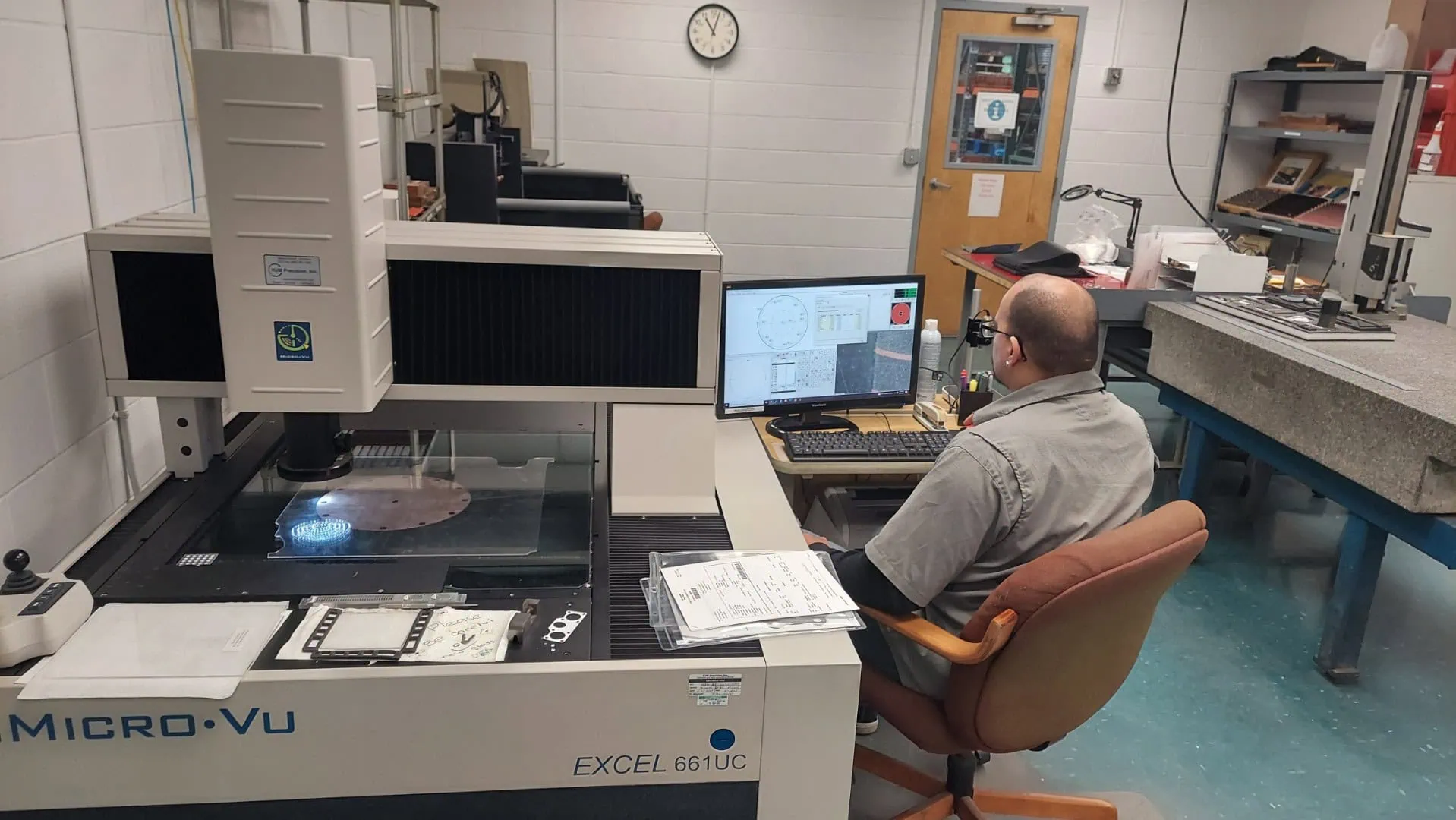

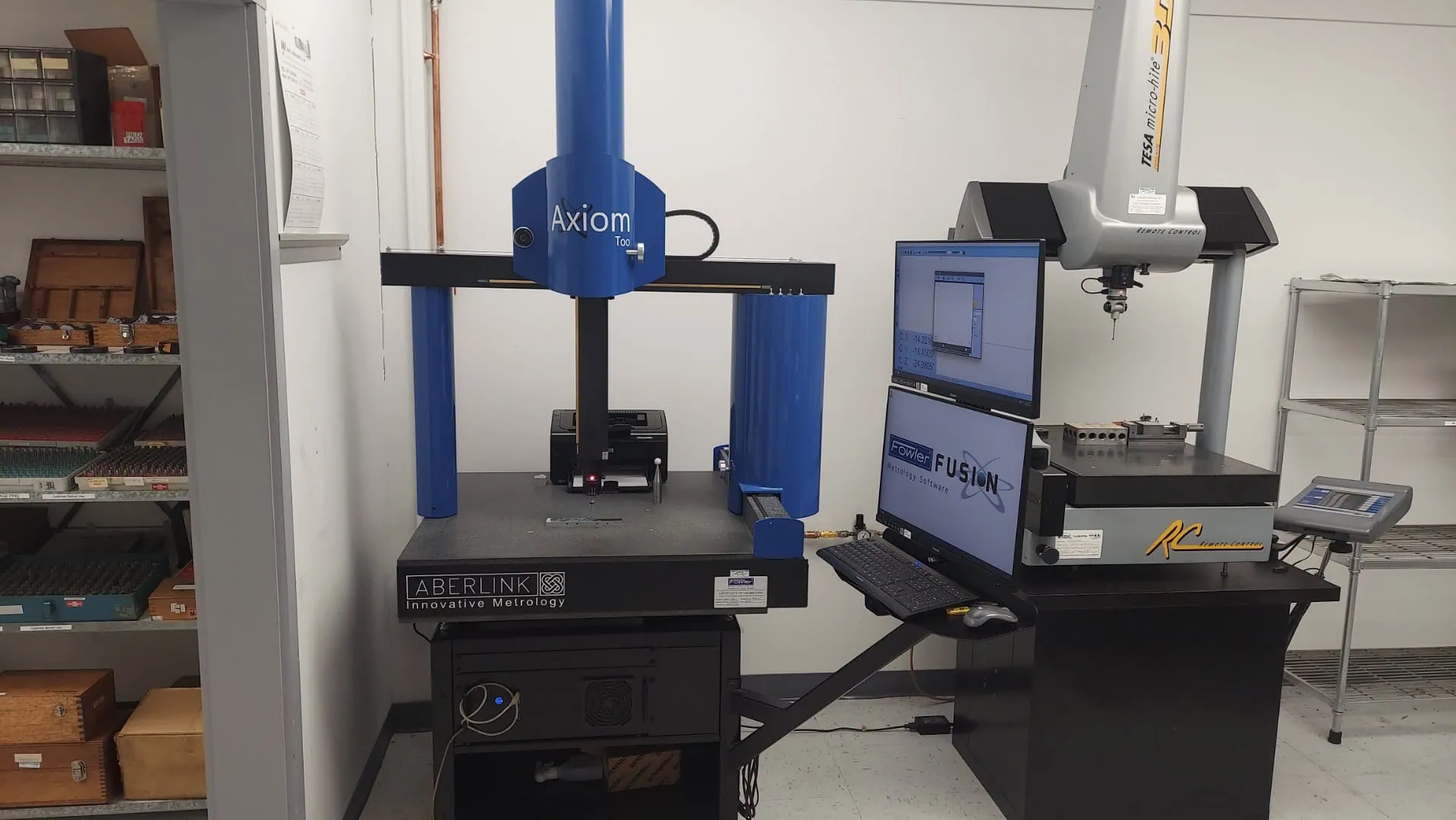

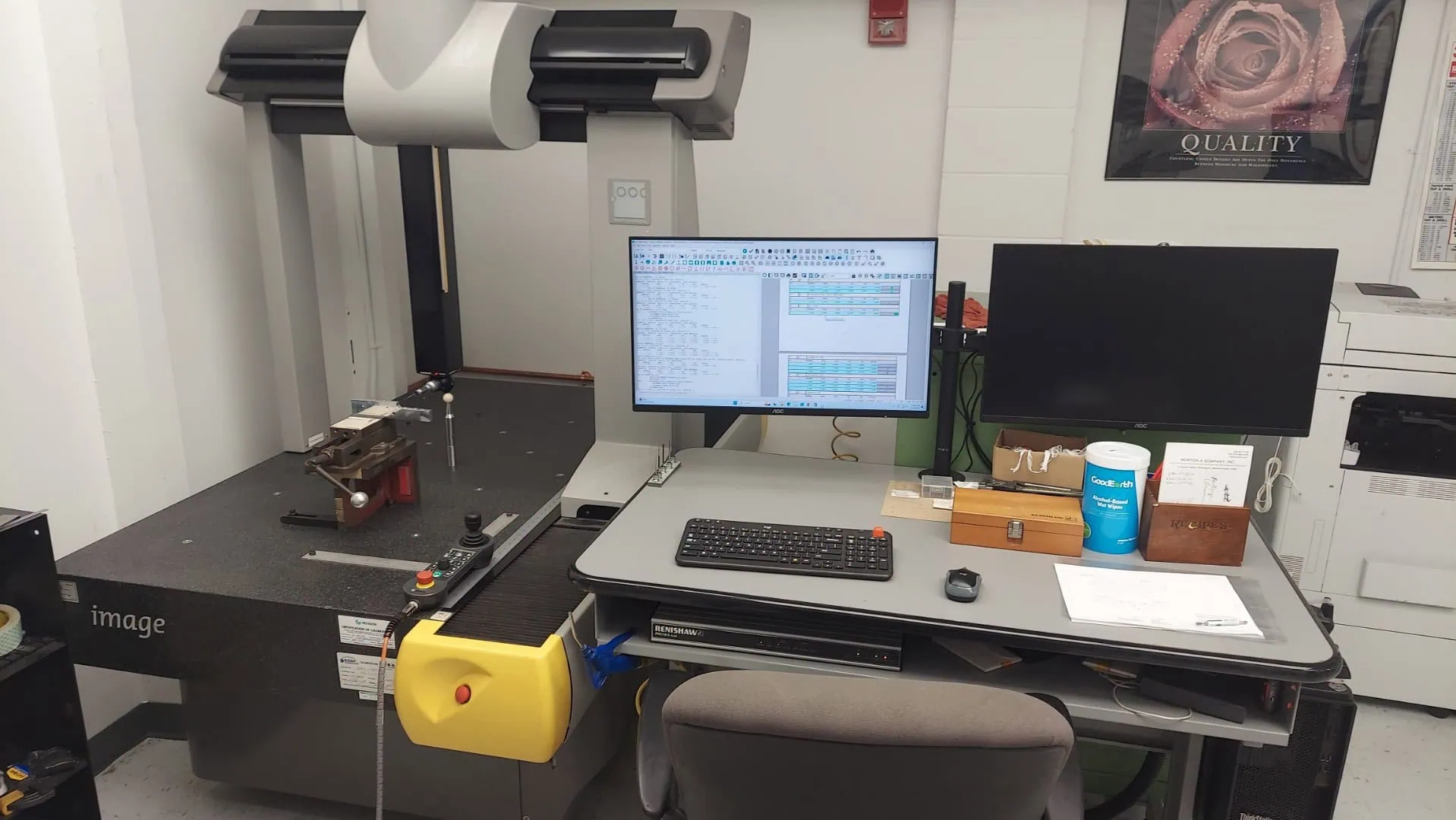

- Can inspect precision dimensions with up to .0001” accuracy

- Has (2) isolated inspection rooms free of shop dust and particles, in a climate-controlled environment

- Utilizes (3) CMM, (2) Micro Vu non-contact measuring machines, and numerous comparators and Micro-Hites throughout various departments

- Is stocked with assorted calipers, micrometers, and gages for any geometry

- Calibrates all inspection equipment throughout the facility according to a documented schedule

- Inspects first-piece, last-piece, and in-process depending on lot size or as frequently as requested

- Can store records, inspection programs, and inventory for repeat orders to ensure consistency

- Provides FAI’s, PPAP’s, CPK Analysis, and inspection reports upon request

- Scrutinizes over all notes, title block features, and GD&T provided on part prints

- Adheres to the latest ISO standards and EPA Regulatory Compliance requirements