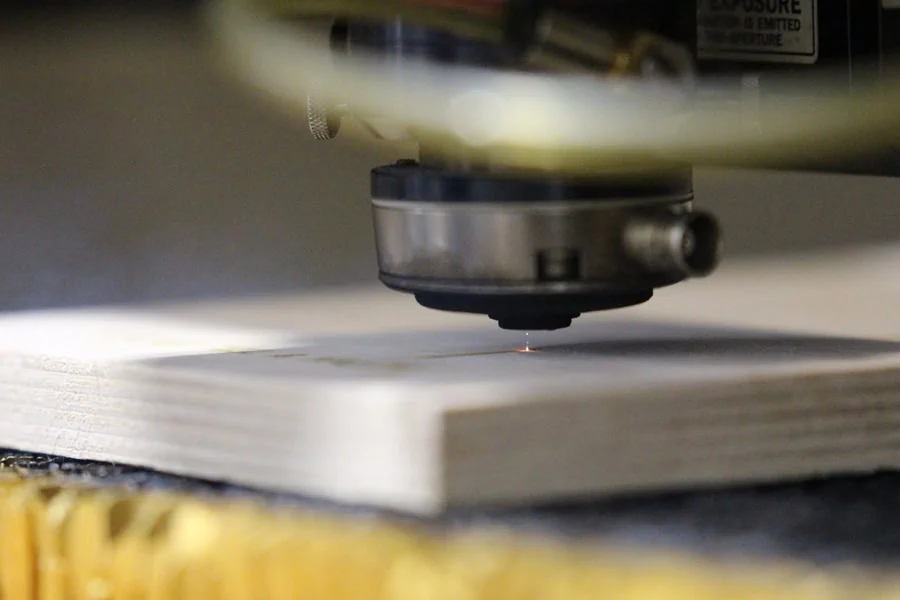

United Tool & Machine offers laser cutting of both metal and non-metal materials. Our fiber laser for cutting metal can hold a sheet up to 24”x48” and tubes up to Ø2”, cutting up to 0.250” thick stock. Our CO2 laser for cutting non-metals, can hold a sheet up to 48”x48”and can cut through much thicker parts depending on the material properties, as well as etch and engrave. The laser beam is consistent enough to maintain tolerances as tight as ±.002”.

Laser Cutting Manufacturing Processes

The acronym LASER stands for Light Amplification Stimulated Emission Radiation. Laser cutting can be compared to cutting with a computer controlled miniature torch. Industrial laser cutting is designed to concentrate high amounts of energy into a small, well-defined spot. The width (or kerf) of the beam is approximately .003-.006” in diameter when using short wavelength lasers. The resulting heat energy created by the LASER melts, or vaporizes materials in this small-defined area and a gas (or a mixture of) such as oxygen, CO2, nitrogen, and or helium are used to blow the vaporized material out of the resulting channel. The beam’s energy is applied directly where it is needed, minimizing the heat affected zone surrounding the area being cut to prevent flames, flashing, or overburn.

Laser Cutting Advantages

There is almost no limit to the cutting path of a LASER. The point can move in any direction. Small diameter holes that cannot be made with other machining processes can easily and quickly be done with a LASER.

The process is forceless allowing very fragile or flimsy parts to be cut with little or no support. The part keeps its original shape from start to finish.

It is ideal when production quantities or prototyping does not justify producing tooling for stamping or die cutting.

Materials that cannot be machined by other means because of lack of conductivity, abrasiveness, or hardness can usually be cut using a LASER. Materials with high reflectivity can also be cut but special precautions must be taken.

Other Advantages

LASERS can cut at very high speeds. The speed at which materials can be processed is limited only by the power available from the laser. Laser cutting is a very cost effective process with low operating and maintenance costs and maximum flexibility.

With their speed, flexibility and accuracy Lasers have become an ideal choice for cutting and scribing the following materials:

- Leather, Fabric, Rubber

- Wood, Plywood, Wood Veneer, Cardboard, Paper Products, Matte-board, Plastics, Acrylic, Ceramics, Composites, Fiberglass, Foam, Laminates, Polyester, Delrin, Nylon, Mylar, Vinyl, Masonite Kevlar, Velcro, Teflon

- Ceramic Substrates, Alumina

- Steel, Stainless Steel, Aluminum