Background

Flat, non-metal parts such as decals, gaskets, seals, packaging, and inserts can easily be blanked using steel rule dies. ‘Kiss-cuts’ may also be included to crease, perforate, or cut to a specific depth without completely cutting through wherever necessary, as in a sheet of stickers. These dies use a plywood, acrylic, or steel board with the profile of the desired part cut into it, and a ‘steel-rule’ blade with a razor sharp knife’s edge formed into shape for inserting into the channel of the board. The assembled board is placed in a press over material to operate like a cookie-cutter for nesting cuts to minimize scrap. Steel rule dies are the most cost-effective method for large-scale production stamping.

Process

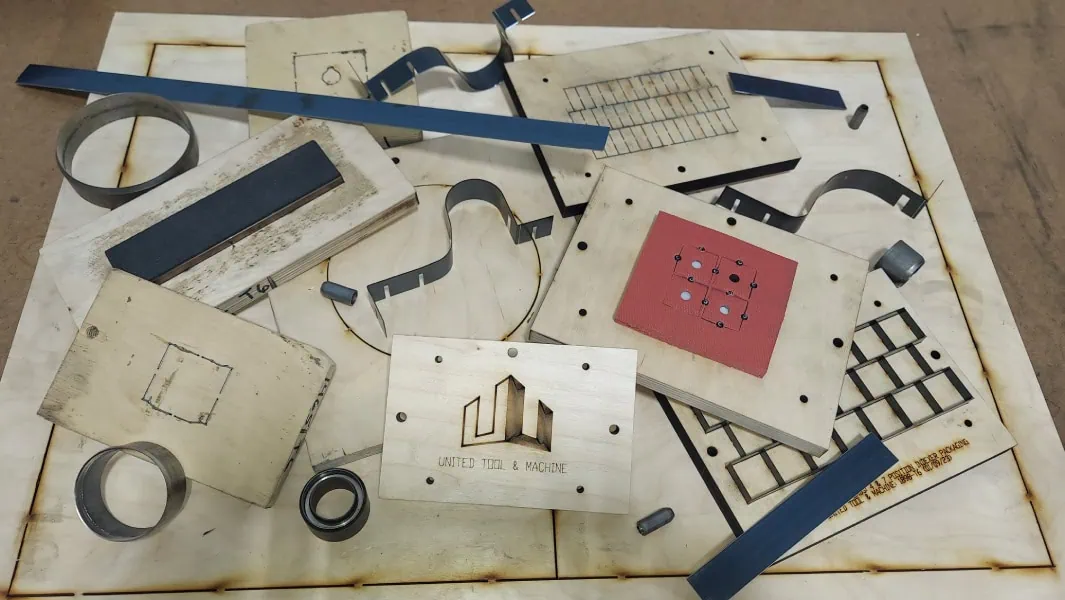

Our engineers will generate a DXF of your part in CAD, prepped with notches, proper punch sizing, and altered corner conditions when applicable. We will use the DXF to automatically CNC bend the steel rule blade(s) into shape with notches, cut to length, and mitered as needed. Our CO2 laser will also use the DXF to CNC cut the profile into plywood boards. The board and steel rule are carefully assembled, and any required punches are inserted, with foam rubber ejection material added last. We then make a first-piece hit in one of our 10 non-metal presses including beam, clicker, hydraulic, and 2 traveling head presses. The initial parts are fully inspected to the tolerances on your print prior to running your full production order. The entire process from order receipt, to DXF layout, to bending steel rule, to laser cutting board, to assembly, to first piece inspection, can occur in as little as 24 hours.

Requirements

- Maximum Stamping Tonnage: 50 Ton

- Maximum Coil/Sheet width: 5 feet

- Maximum Part Footprint: 31.5 x 48”

- Maximum Part Thickness: Depends on compressive properties of material

- Thicker compressive materials such as foam and sponge may have a slightly hour-glass shaped cross-section/edge-condition

- Lead-Time: As little as 24 hours!