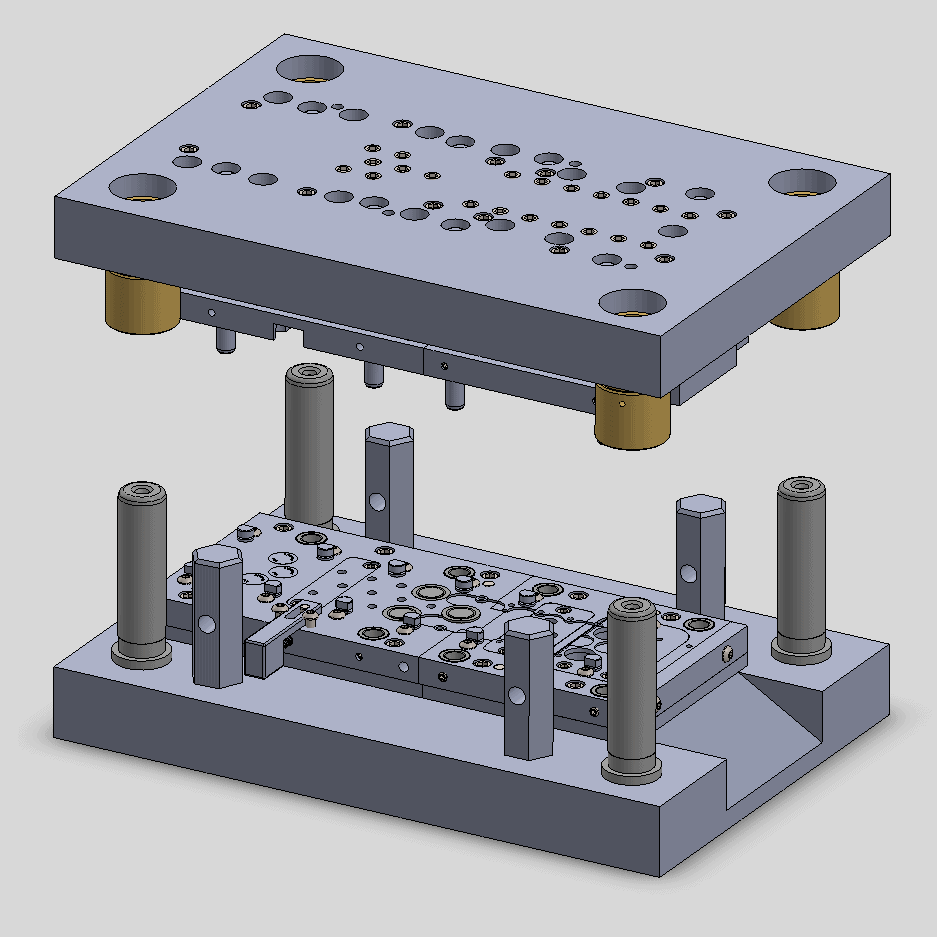

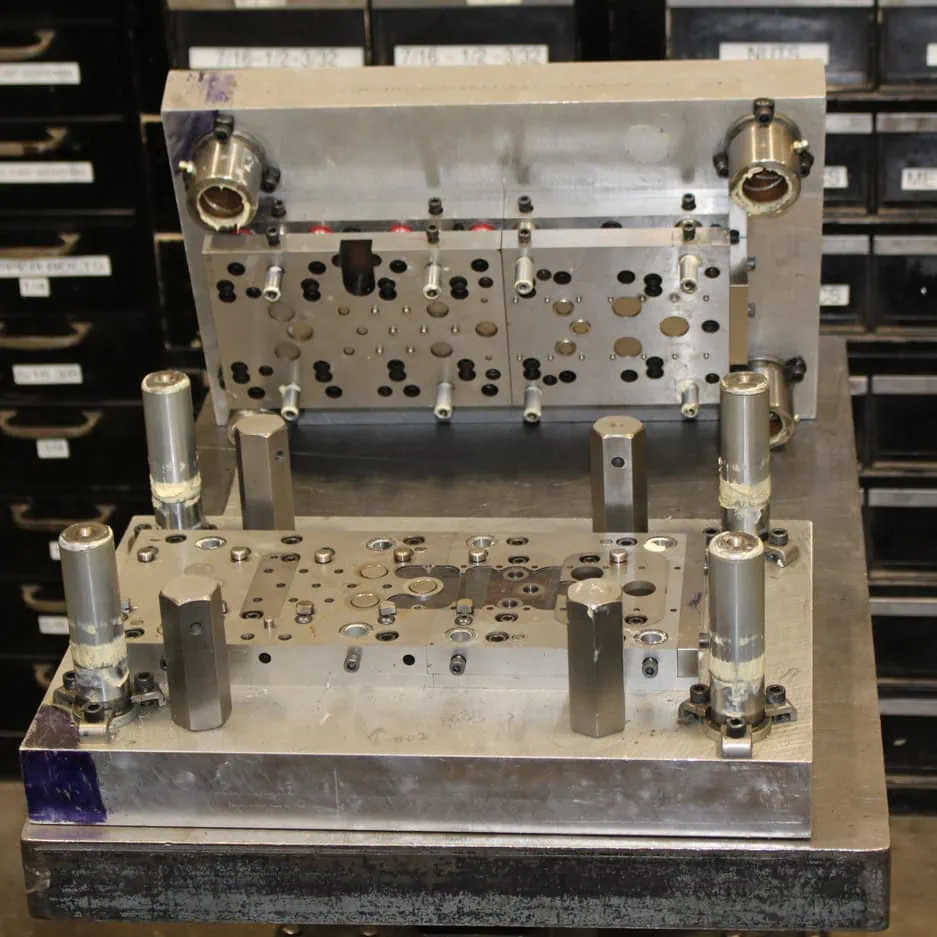

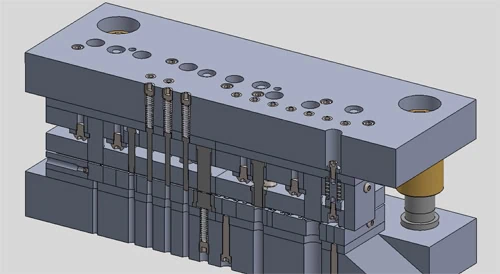

Software

Our designers utilize SolidWorks 3D CAD modeling software and AutoCAD for 2D layouts, but we welcome you to send a variety of other file types (STEP, DXF, DWG, IGES, Parasolid, etc) if available, however a detailed PDF is sufficient to quote. We also use Logopress3 Die Design automation ad-on for SolidWorks to expedite quoting and shave weeks off the design process and troubleshooting to get parts to you faster.